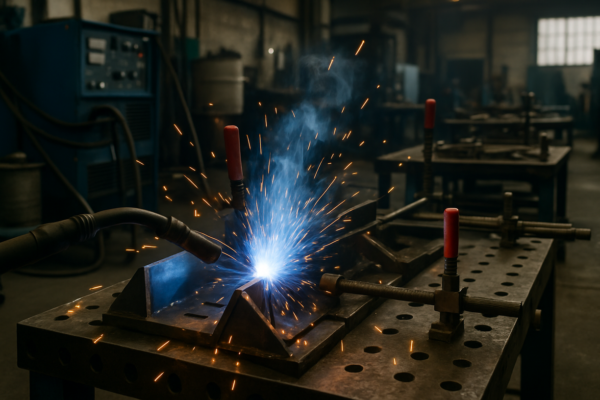

Your Reliable Partner for Custom Welded Parts Since 1993

Precision Welding Solutions from 100pcs MOQ

At Prime, we specialize in producing high-quality custom welded parts including brackets, frames, and structural assemblies. With advanced facilities and certified processes, we deliver strong, reliable, and cost-effective welding solutions for your projects.

Manufacturing of Custom Welded Parts

Prime delivers turnkey welded assemblies—from jigs and brackets to complex frames—combining certified welding, precision machining, and rigorous inspection for strength, repeatability, and on-time delivery.

Production Facilities

Robotic & Manual Welding Lines

MIG/MAG, TIG, spot, and stud welding cells with precision fixtures and turntables enable stable heat input, clean beads, and high throughput for small to oversized welded parts.

- 10+ welding stations (robotic & manual) with modular jigs for rapid changeovers.

- Materials: carbon steel, stainless steel, aluminum; thickness from 1 mm to 25 mm.

- WPS/PQR documented; welders qualified to AWS/ISO standards for repeatable quality.

Technical Advantages

Process Engineering

DFM for weldment design, distortion control, and fixture development—optimized bead path, heat input, and cycle time for stable quality.

Precision & Automation

Robotic welding with seam tracking and pulse control; CNC post-machining ensures datums and holes meet tight tolerances.

Finishing & Traceability

Bead grinding, shot blasting, powder coating, and zinc plating available; full lot traceability and material certificates supplied.

Quality Control

Comprehensive Quality Assurance

Welds verified by visual inspection, macro etch, and NDT (UT/MT/PT) where required; dimensional checks performed on CMM with full reports.

High-Performance Custom Welded Parts for All Industries

Turnkey welded assemblies engineered for strength, flatness, and repeatability—trusted in machinery, construction, transportation, and energy applications.

Welded Brackets & Frames

MIG/TIG welded brackets and rigid frames built on precision fixtures for stable geometry and load-bearing performance.

Structural Weldments

Heavy-duty bases and columns with controlled distortion, verified by NDT when required for safety-critical use.

Sheet-Metal Welded Assemblies

Enclosures, guards, and housings with TIG seams, deburring, and cosmetic finishing for visible surfaces.

Stainless Steel Weldments

Clean TIG welding with passivation and brushing; ideal for food, medical, and corrosive environments.

Aluminum Welded Assemblies

Lightweight frames and fixtures with controlled heat input to preserve strength and dimensional stability.

Custom Welded Fabrications

Built-to-print assemblies with machining, tapping, and finishing—powder coat, zinc plating, or e-coat available.

Prime Custom Metal Welding Process

From fixture design to final coating, our welding workflow delivers strong, dimensionally stable assemblies with full traceability and repeatable quality—ready for your production lines.

1. Requirements & Weldability Review

Align CTQs, loads, materials, and standards (AWS D1.1 / ISO 3834). DFM recommendations cover joint design, access, and tolerance stack-up to minimize cost and risk.

2. Process Plan & Quotation

Provide WPS/PQR route, heat input targets, sequence, and cycle times. You receive a detailed quotation including timeline, inspection plan, and documentation package.

3. Fixture Design & Tooling

Engineer modular jigs with 3-2-1 locating to control flatness and parallelism. Fixtures accelerate changeovers and stabilize dimensions for both robotic and manual cells.

4. Material Prep & Edge Conditioning

Source certified steels, stainless, or aluminum. Laser/plasma cut, machine, and bevel; clean edges and set root gaps to spec for consistent penetration.

5. Fit-Up & Tack

Components are clamped in fixtures to control gaps and squareness. Tack welds lock geometry and reduce cumulative distortion prior to final welding.

6. Welding Execution (Robotic & Manual)

MIG/MAG, TIG, spot, or stud welding executed to WPS parameters with monitored voltage, current, wire feed, and travel speed for repeatable bead quality.

7. Distortion & Metallurgy Control

Apply optimized sequence, back-stepping, pulse modes, and interpass temperature control. Stress-relief or normalizing is added where required by spec.

8. NDT & Dimensional Inspection

Visual inspection plus MT/PT/UT as specified. Datums, holes, and flatness verified on CMM; full reports (FAI/PPAP/COC) available.

9. CNC Post-Machining & Hardware

Machine critical faces and bores; drill and tap to tolerance. Install PEMs/studs or bushings where specified to finalize the assembly.

10. Surface Finishing & Corrosion Protection

Bead grinding, shot blasting, powder coat, e-coat, zinc plating, or passivation. Coating thickness and cosmetics verified to spec.

11. Packaging, Logistics & Support

VCI bags, foam, and reinforced crates with barcode labels and full traceability. Terms EXW/FOB/CIF/DDP; ongoing engineering support and fixture maintenance included.

Applications of Customized Metal Welding Parts

Prime provides engineered welded assemblies for industries worldwide. From structural steel frames to precision enclosures, our custom welding solutions ensure reliability, durability, and compliance with the most demanding standards.

Automotive

Chassis frames, suspension brackets, and exhaust assemblies welded for dimensional stability, fatigue resistance, and lightweight strength.

Aerospace & Defense

Lightweight but strong welded housings, frames, and support structures meeting stringent aerospace tolerance and performance requirements.

Industrial Machinery

Heavy-duty bases, brackets, and housings welded for high load capacity and dimensional precision in demanding industrial environments.

Energy & Power

Turbine supports, generator frames, and solar/wind structures welded to withstand thermal cycling, vibration, and long-term fatigue.

Oil, Gas & Chemical

Pressure vessels, storage tanks, and pipeline assemblies welded from stainless and duplex steels for corrosion resistance and safety.

Food & Medical

Clean, polished stainless welded housings and guards designed for sanitary environments, resistant to corrosion and easy to maintain.

Construction & Infrastructure

Structural beams, connectors, and reinforcement brackets welded to ensure safety, reliability, and weather resistance in infrastructure projects.

Rail & Heavy Transport

Bogie frames, couplers, and heavy welded structures designed to resist fatigue and impact in long-term transport applications.

Send your drawings, material specifications, and volumes — we’ll suggest the optimal welding process and provide a tailored quote within 24 hours.

Our Factory Insight

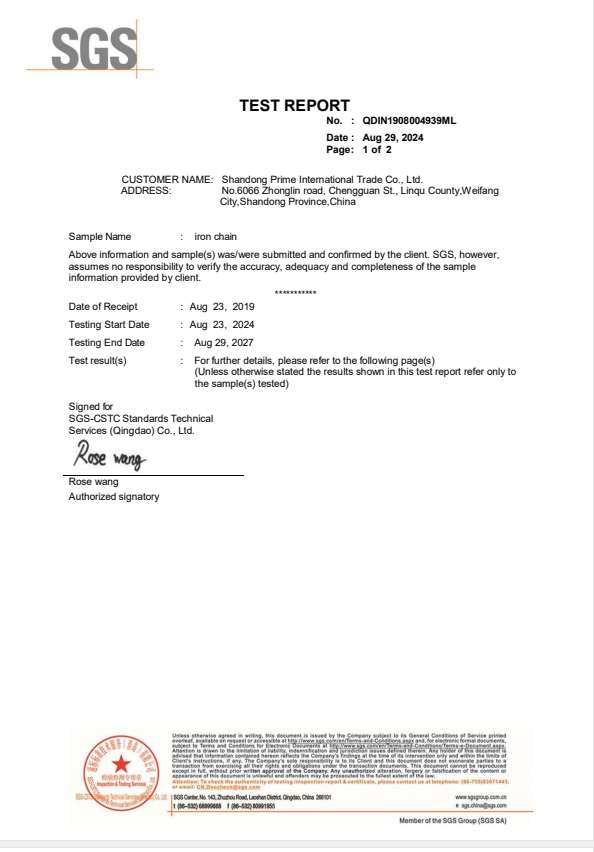

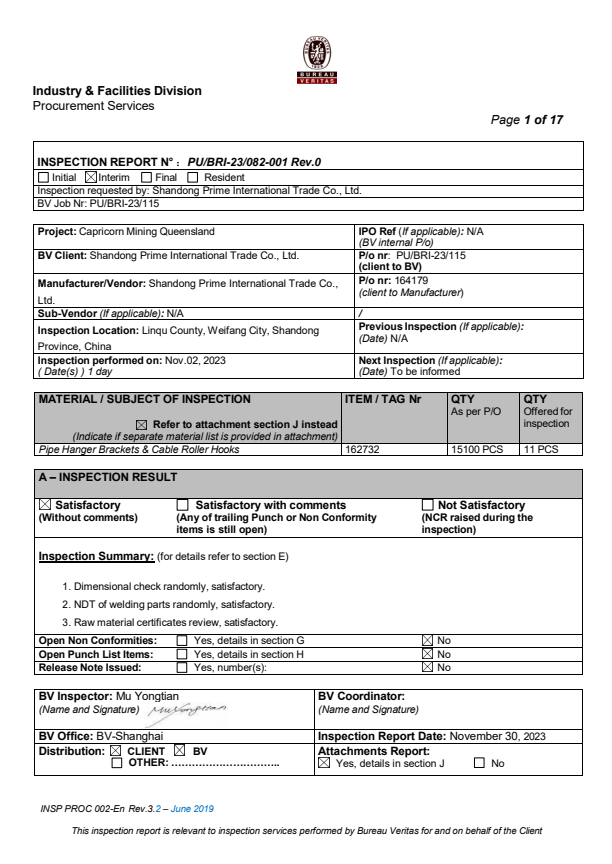

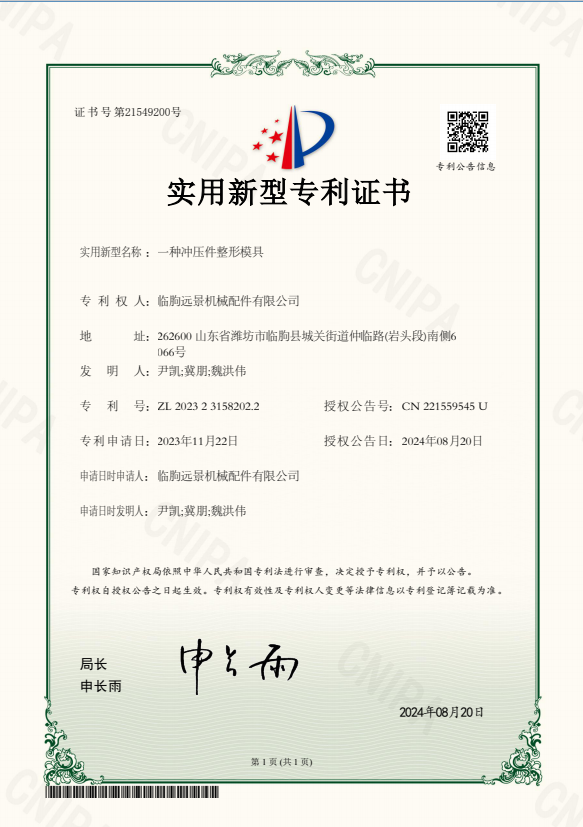

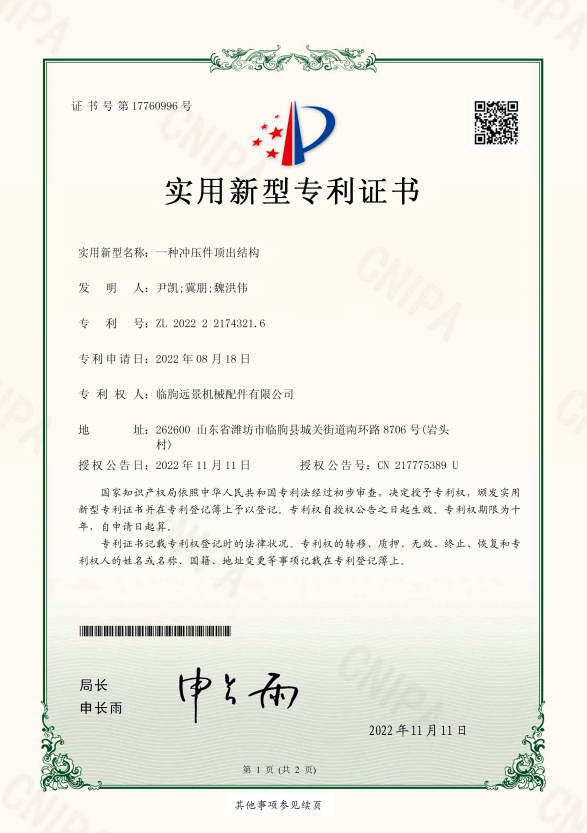

Certificates & Honors

Our commitment to excellence is reflected in our industry certifications and accreditations, which ensure the highest standards of supply chain management for custom metal parts.

Our Commitment to Excellence

Need Custom Certification Information?

We are well aware that different markets and industries have different requirements for certification. With more than 30 years of export experience and ISO international quality systems, we can provide detailed and standardised certification information for your target market or specific application, ensuring smooth customs clearance and compliance with local regulations. Welcome to contact Prime compliance team, we will provide you with the required documents quickly and accurately, so that your procurement and sales worry-free.

Just a Few of the Partners Who Trust Our Quality

*Logos are property of their respective owners.

What Our Customers Say

Real feedback from global buyers who trust us to deliver high-quality, customized industrial components.

Harry M.,New York

Purchasing Manager – Metal Components

We’ve sourced CNC machined parts from Prime for over two years. The precision is consistently excellent, tolerances are spot on, and their team is responsive and professional. Fast lead times and secure packaging make them a reliable long-term partner.

Robert J., California

Strategic Sourcing Specialist – Industrial Hardware

The forged components we received from Prime were top quality — strong material integrity, accurate dimensions, and zero defects. Their team understood our specs clearly and delivered right on schedule. Great supplier for high-stress applications.

Emily T., Texas

Supply Chain Buyer – Custom Metal Parts

We ordered a batch of custom metal welded assemblies from Prime, and the quality was outstanding. The welds were clean, uniform, and met all our strength requirements. Communication was smooth, and delivery was faster than expected.

Get Your Custom Solution & Quote

REPLY WITHIN 24 HOURS

Start a Conversation with Our Experts

When you contact us, you get more than just a price. You get a dedicated partner.

- ✔ 30+ Years of Manufacturing Excellence, Direct from Our Factory

- ✔ Custom-Engineered Solutions for Your Needs

- ✔ Global Shipping & Logistics Support

- ✔ A Transparent, No-Obligation Quote

- ✔ 100% Confidentiality Guaranteed

Your email information will be kept strictly confidential and our business staff will ensure that your private information is absolutely safe!